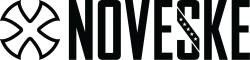

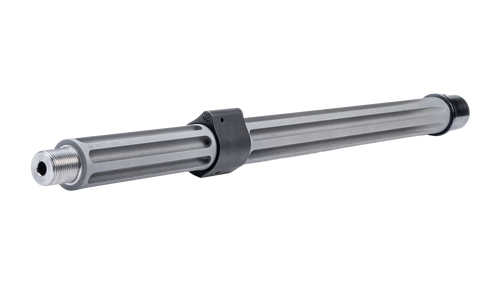

A family of precision 6mm Advanced Rifle Cartridge (ARC) stainless barrels featuring Noveske’s Disruptive Deep Fluting (DDF), hand-polished Noveske Match chambers, and premium finish/workmanship. Each barrel is individually serialized for QC and ships headspaced with a DLC-coated Noveske 6mm ARC bolt.

-

Material: 416R Stainless, 1:7 twist, 3 lands & grooves

-

Hand-polished Noveske Match 6mm ARC chamber

-

Individual serialized barrel for quality control

-

Noveske marked low-profile gas block (Lo-Pro), .936″ journal, pinned to barrel

-

Extended, hand-polished feed ramps

-

60° muzzle crown

-

Bead-blasted finish

-

5/8″ x 24 muzzle threads

-

Includes headspaced, DLC-coated Noveske 6mm ARC bolt and gas tube for respective gas system

| Barrel Length | Gas System | Barrel Weight |

| 12.5" OG | Mid-Length | 25oz. |

| 14.5" Afghan | Mid-Length | 28oz. |

| 18" SPR | Rifle Length | 34oz. |

The Disruptive Deep Fluting (DDF) is an external barrel structure designed to significantly reduce primary (blast compression and expansion) and secondary (sinusoidal resonance) wave events in barrels, improving accuracy, reducing heat, and extending barrel life. Using data from the 2024 TACOM HO Finite Element Analysis (FEA) study. Noveske’s Combat Systems Development & Support program launched an R&D project. The goal was to determine the optimal surface area per linear inch to effectively disrupt these wave events while maintaining the lightweight barrel contour already used by U.S. Special Operations personnel.

DDF Specs

1) Seven (7) Longitudinal Flutes

2) Standardized .980″ Outer Diameter, Minimum Bore Wall Thickness, and .125″ of rounded cut at depth

3) .250″ Maximum Width

4) Fluted maximum length of barrel, minus 1.050″ break for a .936″ gas block journal

5) Total Surface Area per Linear Inch of Fluted Barrel:

a) .224 Bore Barrel – 4.0487sain (vs 3.06sain Standard Contour) +32.31%

b).243 Bore Barrel – 4.0891sain (vs 3.12sain Standard Contour) +31.06%

c).264 Bore Barrel – 4.1446sqin (vs 3.19sqin Standard Contour) +29.92%

d).308 Bore Barrel – 4.2362sqin (vs 3.32sqin Standard Contour) +27.59%

6) More accurate due to decreased sinusoidal resonance

(vibration effecting the stability of the bullet)

7) 25%-40% increase in cooling speed

8) 8%- 13% decrease in weight compared to our standard contour

Accuracy

Constriction of the barrel’s Second Moment of Area (axial flexion) by increasing the barrel’s moment of inertia (structural/material resistance to flexion), vastly reduces load irregularities translated from the barrel to the projectile in accelerated transit down the rifled bore. This reduction in muti-axis wave mode functions allow the longitudinal axis of the projectile to remain better aligned with its velocity vector, thus decreasing precessional instability and increasing trajectory resilience.

Thermal damping

As a byproduct of the drastic reduction in vibration facilitated by the Disruptive Deep Fluting, transfer of kinetic energy into thermal energy as Variable Heat is reduced by 10%, while the cooling speed of the barrel is increased by 25-40% internal temperature at the throat.

Barrel-life increase

Material failure in barrels is caused by the exertion of a force impulse wherein the flexion derived by that force exceeds the material stiffness provided by its temperature moment. The disruptive deep fluting reduces both the flexion imposed on the barrel by the accelerated force impulse and maintains a higher material stiffness due to its ability to maintain a lower temperature, thus increasing barrel life well beyond that of non structured barrels of the same given metallurgy.